Folding Intubation Box

UPDATE

04/09/20

After a bunch of iterations and some really inspiring meetings, today we came up with a new version of the mock-up that solves a lot of the problems listed yesterday.

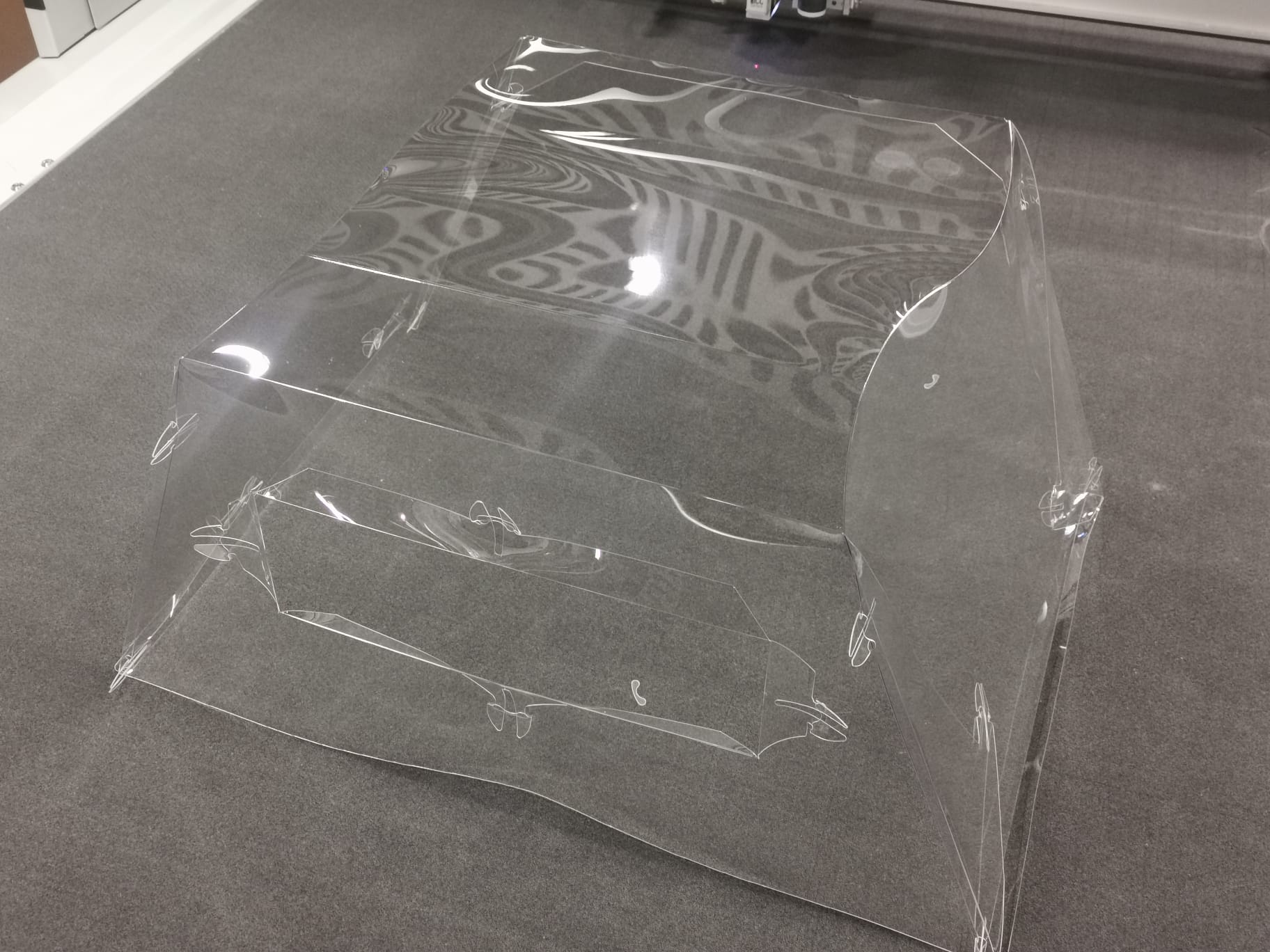

Same photo now but without removing the protective film.

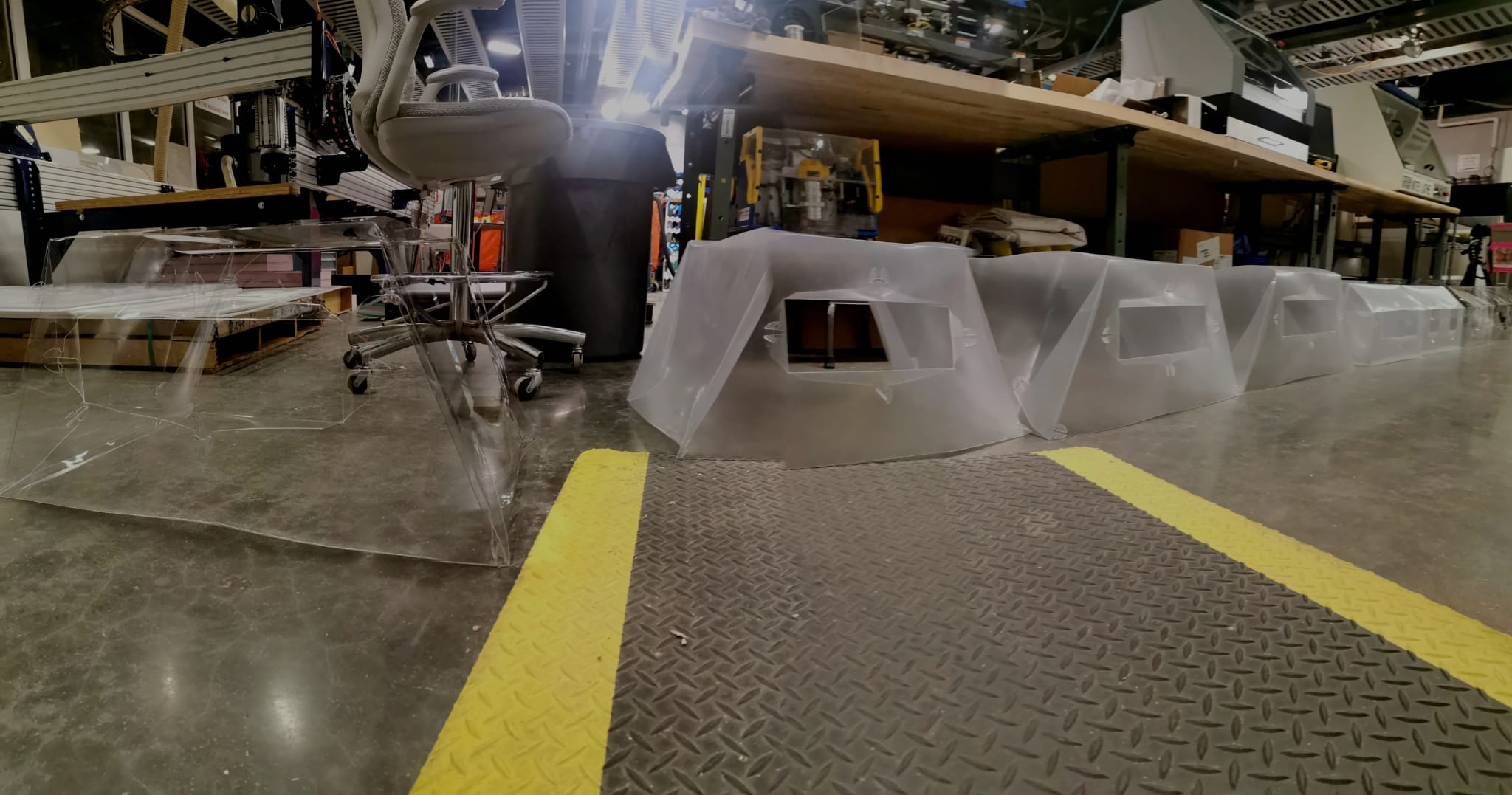

I has been added curved creased lateral hinges due to the bi-stability that provides, compared like adding a chamfer. The total time of cutting the element is 2min 10 seconds with the cutting conditon as z22 blade at 400 mm/min and creasing tool at 1000mm/min. Also, two of this model fits on a 4 by 8 ft PETG sheet.

The folding time has been increased due to all the improvements in the geometry that has been made. Here you can find all the iterations done today. (the actual V9 is the left transparent guy. Its so difficult to take photos to this transparent sheets!)

Excited to know feedback from the doctors tomorrow but looking good.

04/08/20

Based on the feedback that the doctors gave us on the last version of the intubation box Zach and I made, I decided to start from scratch with a total different approach to this intubation box.

It is proposed a folding kirigami intubation box. Points that we are solving immediately form the feedback are:

- Completely transparent

- No sharp edges

- There are no worrying gaps

Added extra interesting features are:

- From a 4 x 8 ft sheet of PETG two intubation boxes can be made

- Cutting on the Zund in 3.5 min per box

- Flat storage

- Protective plastic that helps on deliver non-contaminated devices

On the other hand, there are two aspects we have to iterate on this design. One is it is more than 20 seconds assembly and the other one is that on the patient side of the box, the structural integrity can be improved. We will work on that points towards.

For the time being, this is de 2d design and the folded device.

Mock-up has been made with a 4 by 8 ft PETG sheet 0.5mm thickness. Cut on the Zund with the EOT1 and z22 blade, 100mm linear velocity and the creasing tool at 500 mm/min.